DeLaval’s 50° Herringbone parlour ups the ante for Jersey Manor Farm

26th April 2024

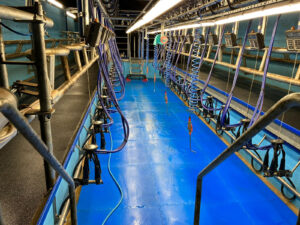

When it was time to consider upgrading his old 12/12 30° herringbone parlour to a bigger, more free-flowing layout, Tim Corner wasted no time in commissioning a DeLaval set-up from T H WHITE Dairy as part of a wider retro-fit at his family-run farm. T H WHITE’s longstanding sales rep, George Eno, was on-hand to quote for a 24/24 50° HB50 Herringbone parlour, and within 6 months, the general building works were complete, the parlour was up and running – and milking times were on the way down.

Tim has been running Jersey Manor Farm in Bicester with his Dad Ian and wife Hannah since 2014, and has seen herd numbers increase steadily to their current level of just over 200. The Jersey breed represents 98% of the herd, with the bloodline going back to the farm’s origins in 1904 – and he’s delighted to see the popularity of the Jersey cow is on the rise again.

T H WHITE Dairy started the parlour installation in October 2022 and the HB50 was operational the following month. ‘The install itself was plain sailing, although MM27 flow metres were hard to get hold of, so soon after the pandemic!’ Tim recalls.

The decision to purchase a 50° Herringbone design has proved to be a wise one for Tim. ‘The HB50 provides much easier access to the underside of the cows thanks to the wider angle the cows present at – and it’s much more comfortable to operate than the old set-up,’ he explains. ‘You’re not leaning and reaching to get to the cows, you’re stood up nice and straight with everything right there in front of you. The additional accessibility and visibility are spot-on.’

Yield and productivity gains are now being seen as the new parlour install was also aligned with a transition from loose housing to cubicles. With both new systems in place, Tim is delighted to see how well the cows have adjusted – only a handful of the 200 still need a little nudge here and there. ‘They’re well-trained on cubicles now – and more than happy to go in, get milked, and get back to their beds’, Tim smiles. ‘The quickest cows “got it” in 24-48hrs, while the slowest took about two weeks before they were fully comfortable with the new systems.’

And crucially, milking times have improved as a result. ‘The old parlour saw 190 cows going through in 5hrs, whereas the new parlour milks 200 cows in just over 2hrs. The revised cow flow is a joy to watch – cows are never in a hurry to stand around!’ he adds. ‘It’s not just the cows that have taken well to the new parlour, the staff are big fans of it too. There aren’t any posts between the cows, so there’s no risk of the operator’s arm being kicked against an upright. The quicker throughputs have also made managing staff rotas so much easier. The old parlour was very closed-in with a low ceiling and everything felt like it was on-top of you. The new parlour design is very open, with a wider pit, creating a much nicer environment for cows and humans alike,’ concludes Tim.

Contact George Eno at the T H WHITE Dairy team on 07483 064724 for more info on the design and installation of DeLaval’s conventional parlour range.