DeLaval’s VMS milking system is the right choice for the Barkers

2nd May 2023

There’s a lot going on at North Hill Farm these days. If it’s not the production of the highly popular ‘Udderly Fresh’ range of raw milk products, or the ‘poo power’ partnership with Arla to create environmentally-friendly BioGas, it’s the stream of happy cows using two newly-installed DeLaval VMSTM V300 robotic milking stations!

Located just outside Aylesbury, Ian Barker has been running the 250 acre farm since 1978. He’s seen a lot of change since then, both in terms of the wider industry’s ever-increasing reliance on new technology and the impact this has had on the diversification of his own farming business.

It was just after the summer of 2021, when this impact was arguably felt most keenly. Following the disruption caused by the pandemic, recruiting new milking staff became even more of a challenge – so much so, that Ian, together with his son Jim, decided the most sensible solution was to take the plunge and invest in robotics.

A six-month period of research followed, where the leading robotics brands were witnessed in action, tested and reviewed – with DeLaval ultimately emerging as the brand of choice. Why? Jim explains: ‘It was a combination of things really. The overall quality and advanced functionality were clear to see, but it was the fact that the DeLaval approach was the closest match to the way we’ve always liked to milk – seeing our traditional parlour processes mirrored in that way made a lot of sense to us.’

Fast forward to April 2022 and the deal had been done with Chris Newey at T H WHITE Dairy – installation following shortly after, and both robotic stations going live in January 2023.

A key benefit of VMS is the ease with which the cows take to the new system, due to the lack of human interaction. Ian explains: ‘We’re experiencing so many efficiencies, as the cows have established a natural hierarchy, with some choosing to be milked 6-7 times a day! An average milking session takes 7mins, delivering a 10-12kg yield, so the numbers are taking care of themselves with minimal inputs from us.’

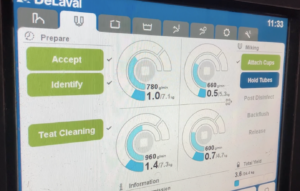

Each teat is first washed then milked, with all teats individually monitored for yield and milk flow.

DeLaval’s ‘3D Camera’, which effectively ‘sees’ in the same way as a human eye, was regarded as a huge plus by the Barkers – as was the ability to closely monitor individual teats. The camera locates each teat one-at-a-time and accurately sprays the teats with Pre Dip, followed by a separate cleaning cup, which prepares each teat for milking. Then, using the 3D camera, the robot arm attaches each cluster cup one-by-one. Sensors detect when each teat has hit its expected yield – so when milk flow ceases, the cups are removed at the right time to avoid any harm coming to the cow, followed by a post dip spray directly on to the teat.

Indeed, robotic milking is understood to be highly beneficial for herd welfare. ‘Cows avoid queuing on concrete for six hours a day, greatly reducing lameness. They’re milked when it suits them, rather than when forced, so the milk is improved in both quality and quantity.’ Jim adds.

Robotics have allowed Jim to spend more time on the raw milk side of the business – something which would have proved difficult otherwise. The VMS system is currently employed across 90% of the herd, with 10% milked separately in a ‘micro dairy’ parlour, producing the raw milk used in the Udderly Fresh products. The Barkers aim to integrate the whole herd under robotics going forward, with a third robotic station already planned to address an increased herd count

Robotics have allowed Jim to spend more time on the raw milk side of the business – something which would have proved difficult otherwise. The VMS system is currently employed across 90% of the herd, with 10% milked separately in a ‘micro dairy’ parlour, producing the raw milk used in the Udderly Fresh products. The Barkers aim to integrate the whole herd under robotics going forward, with a third robotic station already planned to address an increased herd count

Contact Chris Newey at T H WHITE Dairy on 07880 798475 for more info on DeLaval’s Voluntary Milking Systems.